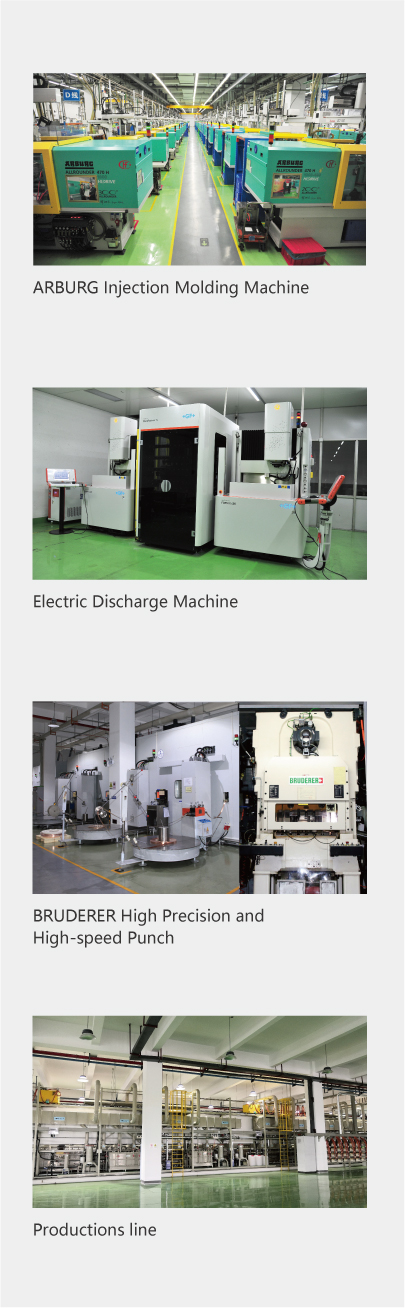

Kemus believes that quality products are made from quality components, and quality components rely on quality molds.

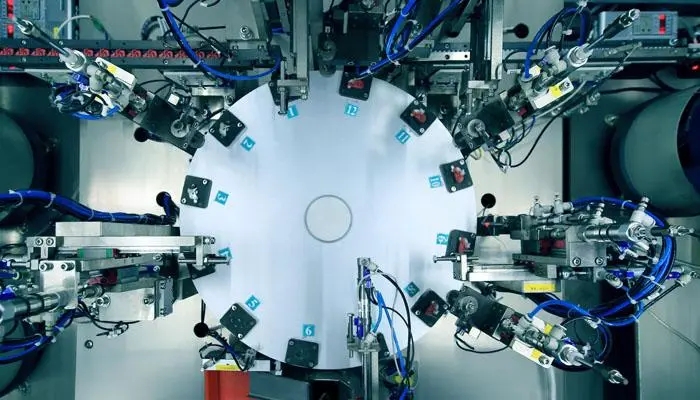

To guarantee quality control of the industrial chain and production efficiency, Kemus established its core competitiveness from parts in the front and assembly equipment in the rear. The self-supply industrial chain has assured high consistency and stability of the products.

Advanced Mold Design And High Precision Mold Manufacturing

(1) Introduce high-precision mold processing from Swiss, Germany, US and Japan etc. and test equipment with machining precision of 1μ.

(2) Establish automation line of mold process and inspection and realize unmanned production in the night shift; annual mold design and manufacturing of 800 plus.

(3) Automatic and informationized system.

High Precision And High Efficiency Parts Production

Build self-supply capability for main parts, master the core technology and advanced management. Annual part output reaches more than 12 billion pcs.

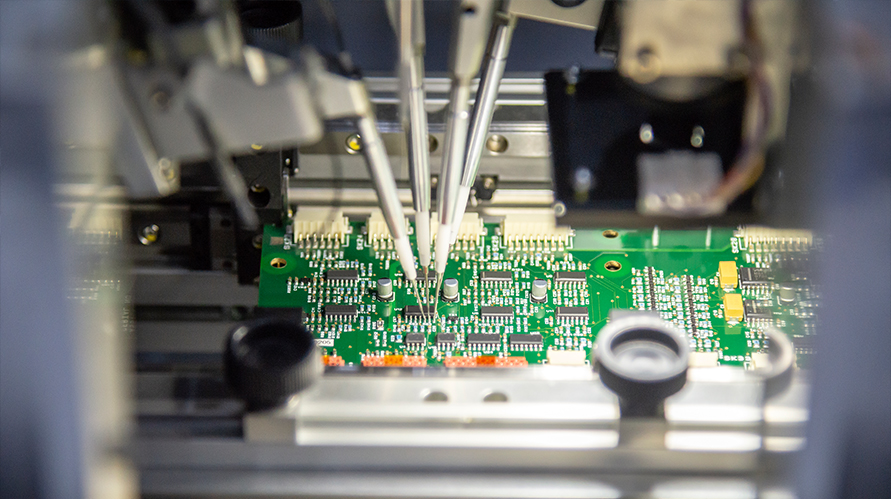

First-Class Design And Manufacturing Capabilities of Automation Equipment

Our company started introducing high-end production lines from overseas since 1993 and has dedicated itself in building automation lines for more than 10 years. Current all high-standard automation lines are self designed and manufactured.

We also established related sales company to provide high standard automation equipment and design and manufacturing service for non-standard lines.

-

Energy efficiency managementAnalyze and monitor electricity consumption data to build a smart energy management and safe electricity consumption platform.Send Inquiry Now

Energy efficiency managementAnalyze and monitor electricity consumption data to build a smart energy management and safe electricity consumption platform.Send Inquiry Now -

Control functionsRealize remote control of circuit breaker opening and closing, and have forced opening function to meet the requirements of prepaid useSend Inquiry Now

Control functionsRealize remote control of circuit breaker opening and closing, and have forced opening function to meet the requirements of prepaid useSend Inquiry Now -

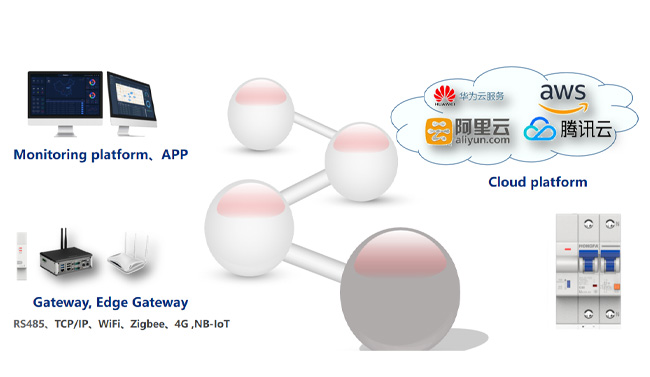

Power Internet of ThingsCircuit breaker IoT system architecture, empowering new forms of low-voltage electrical appliance industrySend Inquiry Now

Power Internet of ThingsCircuit breaker IoT system architecture, empowering new forms of low-voltage electrical appliance industrySend Inquiry Now

-

Electronic Solutions

Electronic Solutions -

Internet of Things Technology

Internet of Things Technology -

Data Center Solutions

Data Center Solutions

-

How to clean the relay?

Dust cover type, solder mask type:

(1) Do not perform hot washing or immersion cleaning.

(2) Please only brush the soldering surface of the printed circuit board.

Plastic sealed type:

(1) Can perform hot washing or immersion cleaning.

(2) Please use alcohol or water cleaning fluid.

(3) Please control the cleaning temperature below 40 °C.

(4) Do not perform ultrasonic cleaning or cut off the lead terminals of the relay, otherwise it will cause the coil to break and the contacts to stick.

For plastic sealed relays, after being installed on the PCB board and soldered, due to different user soldering conditions, the plastic sealing performance of some relays may be damaged. Therefore, if the relay needs to be cleaned as a whole after soldering, please use the soldering conditions recommended by our company and select special plastic sealed products (customer characteristic number 310). Please do not use Freon, trichloroethane, thinner or gasoline for cleaning. -

What are the safety precautions for relays?

Please note that when the relay is working normally, there is a risk of electric shock if you touch it with your hands.

Please cut off the power supply before installing, maintaining and troubleshooting the relay (including terminal blocks, sockets and other connecting parts).

Please note that when connecting the terminals, please refer to the wiring diagram in the product manual and then connect correctly. If the connection is wrong, it may cause unexpected malfunctions, abnormal heating, fire, etc.

If there are defects such as contact adhesion, poor contact, and broken wires, which may endanger other property or even life, please use double safety devices. -

How are low-voltage circuit breakers classified?

1) According to the use category, they are divided into selective type (protection device parameters are adjustable) and non-selective type (protection device parameters are not adjustable).

2) According to the structural type, they are divided into universal type (also known as frame type) and molded case type.

3) According to the arc extinguishing medium, they are divided into air type and vacuum type (currently most domestic products are air type).

4) According to the operation mode, they are divided into manual operation, electric operation and spring energy storage mechanical operation.

5) According to the number of poles, they are divided into single-pole, two-pole, three-pole and four-pole types.

6) According to the action speed, they are divided into general type and fast type. Fast type circuit breakers are divided into AC fast type and DC fast type. AC fast type circuit breakers, usually called current limiting circuit breakers, have a breaking time short enough to disconnect the short-circuit current before reaching the expected peak value; DC fast type circuit breakers can also make the breaking time short enough to disconnect the short-circuit current before reaching the maximum value.

7) According to the installation method, they are divided into fixed type, plug-in type, drawer type and embedded type.

8) According to their uses, they are divided into distribution circuit breakers, motor protection circuit breakers, demagnetization circuit breakers and leakage circuit breakers. -

What are the protection functions of low-voltage circuit breakers?

Early circuit breakers only had one stage of protection for short-circuit instantaneous action. Later, it developed into two stages of protection for overload long delay and short-circuit instantaneous action. Now, the mass-produced small circuit breakers and molded case circuit breakers are all two-stage protection. Circuit breakers have added the so-called "four-stage" protection of overload short delay protection and ground fault protection. In addition, circuit breakers can also achieve undervoltage protection by adding accessories. Contemporary advanced circuit breakers introduce microelectronics technology, which makes it have certain intelligent functions. -

What are the basic technical requirements for a leakage protector?

1) The sensitivity of electric shock protection should be correctly and reasonably set, with the general tripping current range being between 15-30mA; the sensitivity of electric shock protection for equipment should be selected based on the equipment's leakage current, typically ranging from 30-300mA.

2) The operating time of the protection device should generally not exceed 0.1s.

3) The protector should be equipped with necessary monitoring devices to prevent the loss of protective function when the operating state changes, such as for voltage-type electric shock protectors, a neutral wire grounding device should be installed. -

What are the characteristics of a three-pole leakage protector?

Three-phase leakage circuit breakers, in terms of their construction and principle, do not fundamentally differ from single-phase household leakage circuit breakers.

They simply have more poles in the main switch and a higher rated current. They also consist of a leakage detection element, signal discrimination, amplification, actuator, and main switch all integrated into one unit.

Types include three-phase three-wire and three-phase four-wire, with rated currents available at levels such as 40A, 63A, 100A, and 250A.

Currently, the main switch of a three-phase leakage circuit breaker typically uses a plastic enclosure air switch, which itself has overload and short circuit protection functions.

By extending the switch housing to include leakage protection functionality, the three-phase leakage circuit breaker generally serves as a multi-function protective switch.

Air switches are among the more advanced switches in low-voltage applications, especially noted for their good arc-quenching capability of the main contacts, strong switching capacity, and reliability and durability.

The wiring of the leakage circuit breaker remains as simple and clear as that of the air switch, making the three-phase leakage circuit breaker most suitable for branch circuit, sub-branch protection, and power load protection. -

What are the precautions to take when using electronic leakage protectors?

Electronic leakage protectors are simple to manufacture and cost-effective, making them a widely adopted type of leakage protector in China. However, they differ from electromagnetic leakage protectors.

Electromagnetic leakage protectors trip using the energy of the fault current, whereas electronic leakage protectors trip using the residual voltage in the fault circuit (when a grounding fault occurs, the circuit voltage drops, and this residual voltage refers to the voltage at the terminals of the leakage protector during the fault, not the voltage negative deviation of the public power grid). When the grounding fault point is close to the leakage protector, the value may be too low to cause the leakage protector to operate and prevent the accident.

Therefore, when using electronic leakage protectors, it is important to ensure that the protector is not installed too close to outlets to guarantee there is sufficient fault residual voltage at the protector.

Additionally, if the neutral line of the circuit is broken, the electronic leakage protector on the circuit will also fail to operate due to the loss of voltage, and holding handheld or portable equipment with damaged insulation could be very dangerous at this time.

Therefore, when using electronic leakage protectors, the aforementioned factors should be considered. -

Why is it only necessary to install a leakage protector with an operating current of 30mA to protect against electric shock to humans?

The International Electrotechnical Commission standard IEC4.79 (Effects of Current Passing Through the Human Body) determines that when the AC 50Hz current passing through the human body does not exceed 30mA, death due to ventricular fibrillation will not occur, which is independent of the moisture level of the human body and the level of contact voltage.

Therefore, international electrical standards stipulate the use of leakage protectors with an operating current not greater than 30mA in all articles for protecting against electric shock to humans.

Accordingly, in locations with a high risk of electric shock such as hospital operating rooms and bathrooms, leakage protectors with an operating current of 30mA can be installed to protect against electric shock to humans.

China currently produces leakage protection zero-sequence current transformers equipped with leakage relays, with through-hole diameters ranging 25-100mm, corresponding circuit currents 100-800A, and the leakage relays they drive have operating currents 50mA-3A, with delays of 0.2-2 seconds. These transformers are also suitable for adding leakage protection to existing lines.

For leakage protection on the main lines of power supplies with large supply ranges, it is often not desired to trip immediately upon an arcing ground fault within the protected area to avoid widespread power outages.

In such cases, the leakage relay can be used to signal an alarm, allowing the identification of the faulty circuit and the local disconnection of the power supply. If a metallic short circuit with a large short-circuit current occurs within the circuit, the electromagnetic trip unit inside the circuit breaker will operate to disconnect the power supply, protecting the line. -

Is it normal for a miniature circuit breaker to heat up during use?

According to the national standard GB10963.1 (equivalent to IEC60898-1), under specified conditions, the maximum temperature rise for various parts of the circuit breaker is:

The terminal for connecting external conductors should be less than or equal to 60K;

The external parts that may be touched during manual operation should be less than or equal to 40K;

The surface of the circuit breaker in direct contact with the mounting surface should be less than or equal to 60K. -

What are the structural components of an electromagnetic AC contactor?

A contactor is mainly composed of an electromagnetic system, contact system, arc extinguishing system, and other parts.

1.Electromagnetic System: The electromagnetic system includes the solenoid coil and core, which is an important part of the contactor and relies on it to operate the closing and opening of the contacts.

2.Contact System: The contacts are the actuating part of the contactor, including main contacts and auxiliary contacts. The main contacts are used to make and break the main circuit, controlling a larger current, while auxiliary contacts are used in the control circuit to meet the requirements of various control methods.

3.Arc Extinguishing System: The arc extinguishing device is used to ensure that the arc generated when the contacts break the circuit is reliably extinguished, reducing the damage to the contacts from the arc. To quickly extinguish the arc upon breaking, contactors are usually equipped with arc extinguishing devices, typically using semi-enclosed longitudinal groove ceramic arc extinguishing covers, and are fitted with a strong magnetic arc blowing circuit.

4.Other Parts: These include an insulating enclosure, springs, transmission mechanisms, etc.