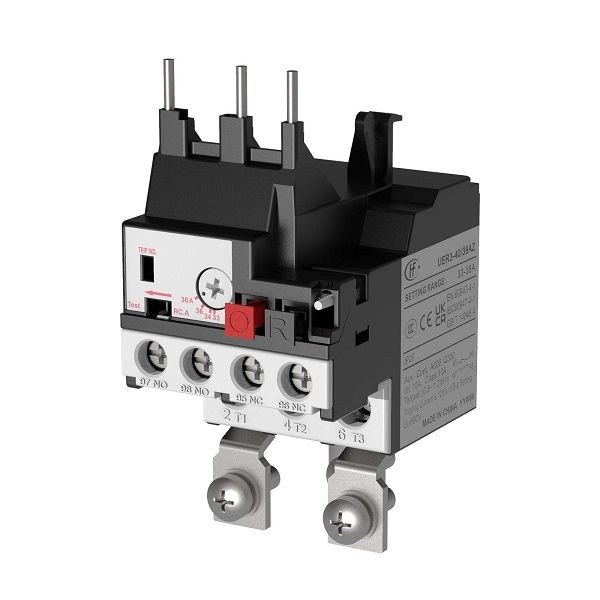

UER3 Thermal Overload Relay

- Product Name: UER3 Thermal Overload Relay

- Is_customized: YES

- Certification: CCC CE UKCA

- Warranty: 18 months

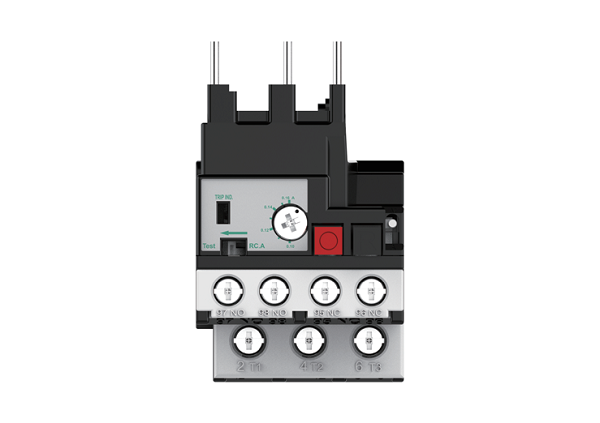

- Number of auxiliary contacts: 1NO+1NC

- Rated insulation voltage Ui(V): 690V

- Network Frequency: 50/60Hz

- Current Settings: 0.1A to 38A

- Tripping class: 10A

- Network Type: AC

- Flame resistance: Current-carrying part: 850°C

- IP Protection: IP20

Overview

Kemus UER3 Thermal Overload Relay:

The UER3 Thermal Overload Relay is a electrical switchgear that leverages the thermal effect of electric current to provide critical protection against motor overloads.Bimetallic strip as sensitive components which made by two different alloys with distinct coefficients of thermal expansion, the UER3 Relay is specifically designed to be sensitive to changes in temperature resulting from excessive current flow. When the current exceeds the preset threshold, the heat generated causes the bimetallic strip to bend due to the differential expansion rates of the alloy layers. This bending movement is the primary mechanism that triggers the relay’s operation, providing thermal overload protection.

The UER3 Relay is integrated into the control circuitry of an electric motor system. Under normal conditions, the current passing through the motor remains within safe limits, and the relay’s bimetallic strip maintains its original position, keeping the motor in operation. However, if an overload occurs, the increased current generates additional heat, causing the bimetallic strip to deflect. This deflection actuates the relay’s contacts, which in turn interrupts the power supply to the motor, effectively preventing damage that could be caused by prolonged exposure to excessive current. The UER3 thermal Overload Relay’s ability to respond to thermal changes makes it an indispensable component in any electrical system where thermal overload protection for motors is top concern.

Product Description

Kemus UER3 Thermal Overload Relay: Precision Protection for AC Systems

Kemus UER3 Thermal Overload Relay is an advanced thermal overload protection solution for AC systems operating at 50Hz or 60Hz, designed to ensure safety and reliability with its current overload and phase loss protection capabilities. With a rated insulation voltage of up to 690V and an adjustable setting current from 0.1A to 38A, this relay is perfect for a wide range of applications. It features temperature auto-compensation to adapt to varying environmental conditions, enhancing its dependability. The relay also includes dual auxiliary contacts for versatile control and an easy-switch button for manual or automatic reset functions.

| No. | Key Feature | Description |

| 1 | Adjustable Current Settings | Customizable current from 0.1A to 38A for precise overload protection. |

| 2 | Temperature Auto-Compensation | Automatically adjusts to environmental temperatures and compensate overload tripping for consistent performance. |

| 3 | Dual Auxiliary Contacts (1NO + 1NC Design) | One normally open and one normally closed for various of control applications. |

| 4 | Manual/Auto Reset Functions | Convenient toggle for quick response to system demands. |

| 5 | High Rated Insulation Voltage | Suitable for systems up to 690V for extensive compatibility. |

| 6 | Clear Operation Indicator | Easy-to-see indicators for status and function checks. |

Working Conditions: Kemus’ Thermal Overload Relay UER3

The operating environment for thermal overload protection is designed by electrical systems that demand high safety and reliability standards. Withstand a range of temperatures and is suitable for both indoor and outdoor applications where protection against environmental factors is necessary. The device is rated for insulation and impulse withstand voltages that ensure its performance in various electrical setups.

Detailed List:

Rated Insulation Voltage (Ui): 690V, ensuring safety for standard electrical systems.

Rated Impulse Withstand Voltage (Uimp): 6kV, providing protection against voltage surges.

Tripping Class: 10A, designed to trip at the specified current to protect the circuit.

Degree of Protection (Front Only): IP20, indicating protection against solid objects but not liquids.

Ambient Air Temperature:

Storage: Ranges from -40°C to +70°C, suitable for extreme temperature storage conditions.

Operation: Functional in temperatures between -5°C to +60°C.

Pollution Degree: 3, indicating a high level of protection against pollution, ideal for dusty environments.

Mounting Type:

Combined Mounting: Plug connect with AC contactor for easy integration.

Independent Mounting: Options for screw mounting or 35mm DIN rail for versatile installation.

Flame Resistance: Current-carrying parts are resistant to temperatures up to 850°C, ensuring continued operation in the event of a fire.

How to Works: Kemus’ UER3 Thermal Overload Relay

The UER3 Thermal Overload Relay is integrated into an electric motor system to offer motor thermal overload protection. It functions by monitoring the current flowing through the motor’s windings.

Connection to the Motor: The thermal elements of the UER3 Relay are connected in series with the motor’s stator windings. This arrangement allows the relay to directly sense the current that the motor is drawing.

Control Circuit Integration: The UER3 Relay’s normally closed (NC) contacts are connected in series with the control circuit of the AC contactor that manages the motor’s power supply.

Current Sensing and Initial State: Under normal operating conditions, the current through the thermal elements is equal to the motor’s rated current. The thermal elements heat up, causing a bimetallic strip to bend due to the temperature rise.

Bimetallic Strip and Lever Action: The bimetallic strip’s bending action is calibrated to a specific point where it makes contact with a lever (or “person-shaped” toggle) without causing it to move significantly. This ensures that the NC contact remains closed, keeping the AC contactor energized and the motor running smoothly.

Overload Detection and Response: If an overload occurs, the current through the thermal elements increases, causing the bimetallic strip to heat up more and bend further. This increased bending pushes the lever, which in turn moves the NC contact.

Circuit Interruption: The movement of the NC contact opens the control circuit of the AC contactor, causing it to cut off power. This action interrupts the power supply to the motor, effectively stopping it and preventing damage due to the overload condition.

Reset Mechanism: Once the overload condition is resolved, the UER3 Relay can be reset manually or automatically, depending on the configuration, allowing the motor to resume operation.

Contractual Warranty:Kemus Sensitive Residual Current Circuit Breaker

Long warranty period reach 18-month warranty period. Even beyond this warranty, we are pleased to exert every effort to address your concerns, focus on & striving to solve problems.

Why Choose UER3 Thermal Overload Relay

Precision Protection: The UER3 Thermal Overload Relay offers tailored thermal protection with adjustable current settings, ensuring precise motor safeguarding.

Reliability Assurance: Its temperature auto-compensation feature guarantees reliable operation across varying environmental temperatures, maintaining consistent performance.

Versatile Integration: With dual auxiliary contacts, the UER3 Relay provides flexible control options, easily integrating with different power sources and systems.

Quick Response Mechanism: Equipped with a manual/auto reset function, the UER3 Relay allows for immediate action in the event of an overload, reducing downtime.

Robust Voltage Endurance: Suitable for high voltage systems up to 690V, the UER3 Relay delivers durable insulation and withstands impulse voltages up to 6kV.

Intuitive Operation Indicators: Clear and visible status lights provide immediate feedback on the system’s condition, ensuring easy monitoring and peace of mind.

UER3 Thermal Overload Relay Symbol Ensures Uncompromising Quality in Motor Protection Solutions

- Multifunctional Design

- Wide Parameter Range

- Easy Installation

- Compact Size

- Durable Materials

- Overload and Phase Loss Protection

- High Sensitivity

- Adjustable Settings

- User-friendly Interface

Comprehensive Motor Protection, Never Leave UER3 Thermal Overload Relay

- Power Systems

- Home Safety

- Textile Machinery

- Precision Thermal Device

- Mining Machinery Monitor

- Oil Rig Equipment

- Chemical Equipment

- Gas Compressor Units

- Petrochemical Pumps

Why Choose Kemus

UER3 Thermal Overload Relay: Essential for Safety

– Thermal overload relays ensure efficient current management and swift fault current interruption in high-voltage circuits, maintaining system safety.

– Providing motor overload protection by tripping the control circuit upon detecting excessive heat from electrical current, preventing motor damage.

– Cost-effective design, widely implemented across industries for reliable electrical system protection.

Kemus' UER3 Thermal Overload Relay Leading Production Facility

– Self-owned UER3 Thermal Overload Relay Manufacturing Facility: Our state-of-the-art factory, equipped with the latest technology, ensures a stable production flow and consistent quality, making it ideal for large-scale electrical safety projects and installations.

– Advanced Production Technology: Leveraging proprietary technology and processes, our Thermal Overload Relay are manufactured with precision, offering superior performance and reliability, essential for critical electrical systems.

– Scalability for Large Projects: With the capability to produce in large quantities while maintaining a stable quality standard, our factory is well-suited to meet the demands of extensive exterior electrical installations and large-scale building projects.

Quality Consistency: Each UER3 Thermal Overload Relay is manufactured to ensure a uniform standard of quality, which is vital for walling systems and other applications where consistent performance is required.

- Pre-Inspection Review: Kemus initiates the inspection with a thorough review of the RCCB's operational history and customer feedback to identify potential concerns.

- Visual and Functional Assessment: Our experts conduct a detailed visual inspection and test the RCCB's functionality, ensuring all components are in optimal condition and operate as intended.

- Performance Testing: Utilizing advanced diagnostic tools, Kemus evaluates the RCCB's performance under various simulated conditions to guarantee sensitivity and response accuracy.

- Certification and Documentation: Upon successful testing, Kemus certifies the RCCB, providing comprehensive documentation for record-keeping and customer assurance.

Exhibition Worldwide

- Direct Factory Price

- Quality Without Compromise

- Supply Stability

- Delivery On Time

- Thoughtful Service

- More Options From Us

- Useful introduction and suggestion

- Less communication, better understanding

Certified management systems, processes and products which ensure the quality of the product you got.

Working with us, you will get

Kemus UER3 Thermal Overload Relay is the leading manufacturer and supplier of Thermal Overload Relay. Kemus UER3 Thermal Overload Relay is also one of the largest wholesale suppliers of electrical protection devices in China.

- Direct Factory Price

- Quality Without Compromise

- Supply Stability

- Delivery On Time

- Thoughtful Service

- More Options From Us

- Useful introduction and suggestion

- Less communication, better understanding

Packing & Delivery

UER3 Thermal Overload Relay FAQ

- What is the UER3 Thermal Overload Relay's primary function? It provides thermal overload protection for electric motors.

- Can the UER3 Relay be used for motors with varying power ratings? Absolutely, its adjustable current settings accommodate a range of motor powers.

- What is the UER3 Relay's response time to an overload condition? It provides immediate response to prevent motor damage.

- Can the UER3 Relay be used in conjunction with other types of overload protection devices? It can be part of a comprehensive motor protection system, complementing other devices like current sensors.

- Can the UER3 Relay be integrated with existing motor protection circuits? Easily, with its plug connect and independent mounting options.

- What are the UER3 Relay's auxiliary contact configurations? It includes one normally open and one normally closed auxiliary contact.

- What is the UER3 Relay's protection degree against solid objects and dust? It has a protection degree of IP20, safeguarding against solid objects and dust

- What are the environmental conditions that could affect the UER3 Relay's performance? Extreme temperatures, dust, and corrosive environments could impact its sensitivity and longevity.

- Is the UER3 Relay designed to withstand mechanical shocks and vibrations? It is built to resist certain levels of mechanical stress, but consult the manual for specific tolerances.

- How does the UER3 Relay differentiate between normal operation and overload? Regular inspections should be scheduled according to the manufacturer's guidelines, typically every 6-12 months.

- How often should the UER3 Relay be inspected to ensure optimal performance? Regular inspections should be scheduled according to the manufacturer's guidelines, typically every 6-12 months.

- Is there a specific procedure to follow when resetting the UER3 Relay after an overload? Consult the user manual for the correct procedure, which may involve checking the circuit and resetting the device.

UER3 Thermal Overload Relay Solutions