Protection of equipment from damage and guarantees of production safety are absolutely important in electrical control systems. Among them, thermal relays—a common protective element—are extensively applied in overload protection of motors and other electrical equipment. However, it is worth noting that although thermal relays are powerful, their original design and scope of application are clearly limited to the field of overload protection, not short-circuit protection. This paper attempts to investigate in-depth this characteristic of thermal relays, examine their working principles, advantages for application, and reasons they are not appropriate for short-circuit protection.

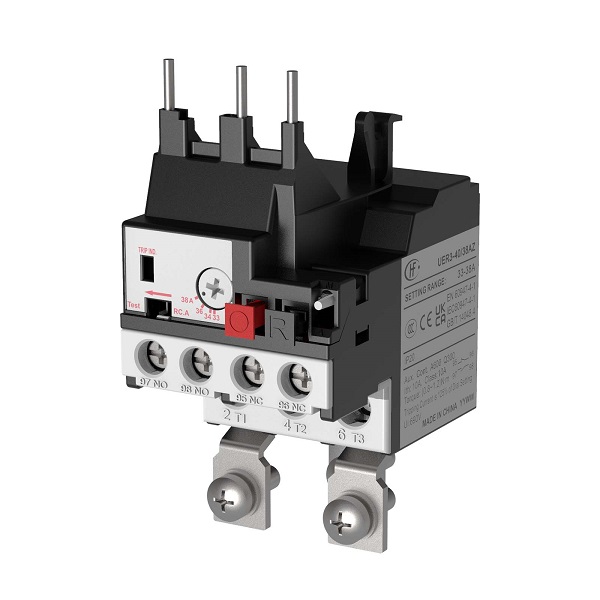

UER3 Thermal Overload Relay

Details of the working principle of thermal relays

The working principle of thermal relays involves the current passing through the bimetallic strip to generate heat, causing the bimetallic strip to bend. This design lets the thermal relay change its response in line with the current size and duration. The thermal impact of the overload current determines the degree of bending of the bimetallic strip, hence the thermal relay may offer exact overload protection. This working concept based on thermal effect, however, also limits its employment under short-circuit conditions since the fast increase in current during a short circuit exceeds the response capacity of the bimetallic strip.

Types and characteristics of thermal relays

Different application needs can be met by designing thermal relays into several forms, such thermal relays with fixed set values and thermal relays with changeable set values. Thermal relays with fixed set values are suitable for standard loads and fixed applications, while thermal relays with adjustable set values provide greater flexibility, allowing users to adjust the level of protection according to specific application scenarios.

Synergy of thermal relays with other protection devices

In practical applications, thermal relays typically constitute an integrated protection system in concert with other safety devices including fuses, circuit breakers and overcurrent relays. Fuses, for instance, can act as the first line of protection to react rapidly to unexpected short-circuit currents; circuit breakers can offer protection when the current exceeds the set value but is insufficient to set the fuse; and overcurrent relays can offer more complex current control and protection. The thermal relay is mainly responsible for overload protection in this system, ensuring that motors or other equipment are not damaged due to long-term overload.

Thermal relays’ maintenance and calibration

Regular maintenance and calibration help to guarantee thermal relay accuracy and dependability. This covers verifying that the bimetallic strip is in good condition to guarantee that there is no damage or deformation; calibrating the current setting value to match the real application criteria; and verifying the contact condition of the contacts to guarantee that the protection action can be consistently started when needed.

Application of thermal relays in modern industrial automation

Thermal relays find extensive application in modern industrial automation not just for conventional motor protection but also in servo motors, frequency converters and other precision control devices in automation control systems. The stable running of the whole system depends on the exact overload protection of thermal relays in these uses.

Future development of thermal relays

Thermal relays are also always evolving and improving with technological development. To increase their response speed and accuracy, certain new thermal relays, for instance, use more sophisticated materials and designs. In addition, the development of intelligent thermal relays, which integrate microprocessors and communication interfaces, can be seamlessly integrated with modern industrial network systems to provide more advanced monitoring and diagnostic functions.

Thermal relays are absolutely indispensable in electrical control systems since they are a typical overload protection tool. Its benefits and dependability in overload protection make it a vital component of industrial and commercial applications even though it is not appropriate for short-circuit prevention. Thermal relays will keep changing to fit a greater spectrum of application requirements and collaborating with other protection technologies will help to guarantee the safe and effective running of electrical systems as technology develops.

Post time: 7 月-16-2024