In the vast sea of electrical engineering, the thermal overload relay ( commonly known as thermal protection, letter symbol FR) is like a shining star, guarding the safety of the motor with its unique light. As an indispensable protection element in the electrical system, the thermal relay provides a solid line of defense for the motor with its exquisite design and reliable performance. Today, we will explore in depth the types of thermal relays, working principles, and how to correctly select and apply them to ensure that the motor can be effectively protected under various working conditions.

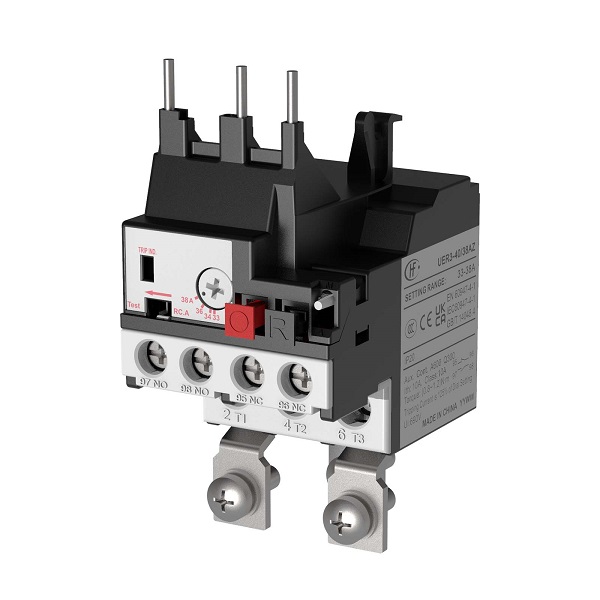

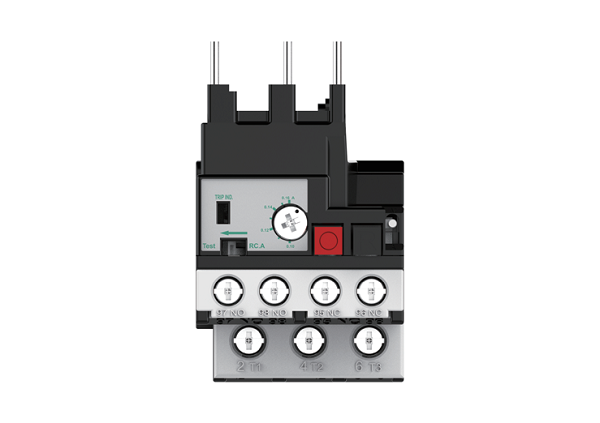

UER3 Thermal Overload Relay

Common types of thermal overload relays

Thermal overload relays ( commonly known as thermal protection, letter symbol FR) have the following types:

(1) Bimetallic type: Use the effect of bimetallic sheets with different expansion coefficients such as manganese nickel and copper sheets bending when heated to push the lever to make the contact move. Abbreviated as thermal expansion and contraction.

(2) Thermistor type: Thermal overload relays (commonly known as thermal protection, letter symbol FR) are made using the property that the resistance value of metal changes with temperature.

(3) Fusible alloy type: The overload current heats up the fusible alloy and melts when it reaches a certain temperature value, which causes the relay to operate (commonly known as thermal protection, letter symbol FR).

Among the three types of thermal relays mentioned above, the most commonly used is the bimetallic thermal relay, which is usually combined with a contactor to form an electromagnetic starter.

Selection of thermal overload relay

Thermal overload relays ( commonly known as thermal protection, letter symbol FR) are mainly used to protect motors from overload. Therefore, when selecting them, you must understand the motor’s conditions, such as the working environment, starting current, load properties, working system, and allowable overload capacity. In principle, the ampere-second characteristics of the thermal overload relay ( commonly known as thermal protection, letter symbol FR) should be as close as possible to or even overlap the overload characteristics of the motor, or under the overload characteristics of the motor, at the same time, at the moment of short-term overload and starting of the motor, the thermal overload relays (commonly known as thermal protection, letter symbol FR) should not be affected (not activated).

The correct selection of thermal overload relays ( commonly known as thermal protection, text symbol FR) is closely related to the working system of the motor. When thermal overload relays ( commonly known as thermal protection, text symbol FR) are used to protect motors in long-term working systems, they are generally selected according to the rated current of the motor. For example, the setting value of the thermal overload relay (commonly known as thermal protection, text symbol FR) can be equal to 0.95~1.05 times the rated current of the motor, or the median value of the setting current of the thermal overload relay ( commonly known as thermal protection, text symbol FR) is equal to the rated current of the motor, and then adjusted.

When thermal overload relays (commonly known as thermal protection, text symbol FR) are used to protect motors in repeated short-term working systems, thermal overload relays (commonly known as thermal protection, text symbol FR) have only a certain range of adaptability. If the number of operations per hour is high, a thermal overload relay (commonly known as thermal protection, text symbol FR) with a speed saturated current transformer should be selected.

Thermal Overload Relay

For special working motors with frequent forward and reverse rotation and frequent on and off, it is not appropriate to use a thermal overload relays(commonly known as thermal protection, text symbol FR) as an overload protection device, but a temperature relay or thermistor buried in the motor winding should be used for protection.

As the guardian of the motor, the selection and application of the thermal relay should be based on the specific characteristics and working conditions of the motor. Although it may require alternatives under special working conditions, when used correctly, the thermal relay can provide effective overload protection. With the development of technology, we expect thermal relays to achieve more intelligent protection functions to ensure the safety and efficiency of electrical systems. Let us continue to explore and apply these technologies to ensure the stable operation of motors and the safety of electrical systems.

Post time: 7 月-16-2024