In the world of electrical engineering, contactors play a vital role. They are the secret to guarantee circuits’ safe and effective running condition. Electricians have to be well-versed in contactors—including their functioning ideas, components, selection points, and other classes. This article will introduce you into the technical world of contactors, investigate the secrets of these electrical components, and make sure you can do it with simplicity in real-world application.

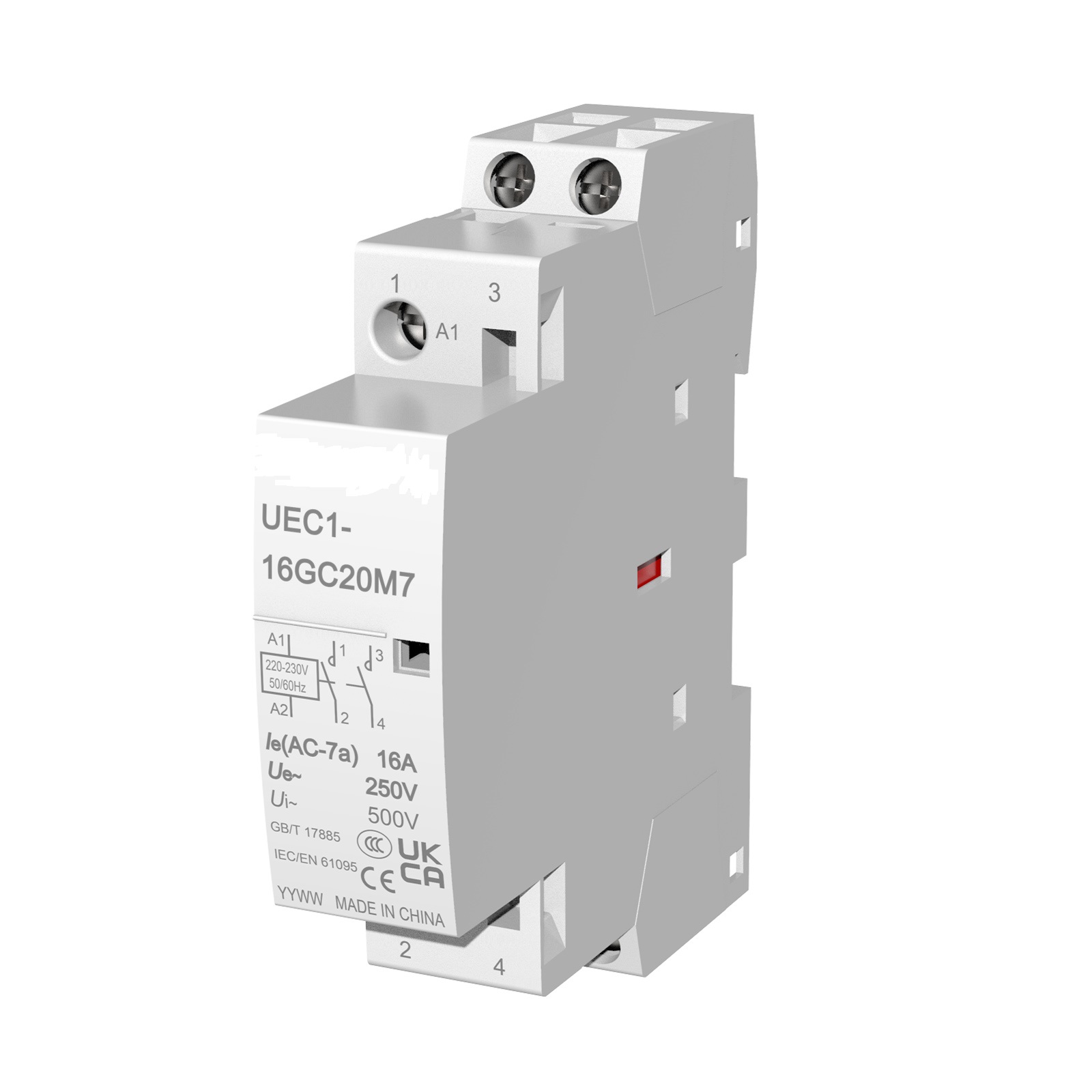

AC Contactor UEC1 series

What is a contactor? What is its function?

Usually employed to protect electrical equipment and control circuit switch, a contactor is an electrical component. Its functioning concept is to realise the start and stop control of electrical equipment by means of on and off of an electromagnet, therefore controlling the switch of a circuit. A contactor’s primary purposes are: A contactor allows one to connect or detach a circuit, therefore realising the start, stop, or switch control of electrical equipment. A remote control system lets one operate this control either manually or automatically. Safeguard electrical equipment. The contactor performs short-circuit and overload protection among other purposes. The contactor can rapidly switch off the circuit when an overcurrent or short-circuit fault develops in the circuit to stop too strong current from damaging the equipment or starting an accident. The contactor can split the circuit into numerous portions to get segmented control of electrical equipment, so enhancing the running efficiency and safety of the electrical equipment. Remote control of electrical equipment and enhancement of the degree of automation and intelligence of electrical equipment can be accomplished by means of the contactor in concert with a remote control system.

What are the components of the contactor?

1. Contact part: This is the core part of the contactor, which has the function of powering on and off. Usually it consists of movable and stationary contacts. The moving contact separates from the fixed contact when the contactor is turned off, therefore stopping the current. Main and auxiliary contacts comprise the contact system. While the auxiliary contact controls other portions of the circuit, the main contact is utilised to turn on and off the main circuit.

2. Electromagnetic mechanism: The electromagnetic mechanism consists of a coil, a moving iron core (armature) and a static iron core. Its purpose is to provide electromagnetic attraction to propel the contact to move and transform electromagnetic energy into mechanical energy. The moving iron core will be drawn by the electromagnetic force when the electromagnetic coil is energised; the moving contact will either directly or via the lever gearbox link the circuit. The moving iron core will automatically recur under the influence of the reset spring when the electromagnetic coil is de-powered; the contacts will separate and the circuit will be severed.

3. Insulation part: mainly composed of insulating materials, used to isolate the electrical part and the mechanical part to prevent current leakage or electric shock. Used to link and fix the contacts and the insulating component, mechanical parts including switch handles and springs also help to manage the functioning state of the contactor.

Arc extinguishing hoods (used to extinguish the arc when the contacts are disconnected), contact pressure spring sheets (used to maintain the contact pressure between the contacts), and reaction springs (used to rapidly separate the contacts after the electromagnet is de-energized) could also be some unique parts used in AC contactors.

How choose a contactor?

Several elements should be taken into account while choosing a contactor to guarantee that it satisfies particular application criteria. These are some typical needs just for reference.

1. Find the load’s type: Choose the kind of contactor based on the load type—AC or DC, motor or other load. One should match the contactor type to the load.

2. Voltage level: The voltage level of the AC contactor should be the same as the load, and the rated voltage should be greater than or equal to the main circuit operating voltage. The rated operating voltage of the contactor cannot be higher than its rated insulating voltage concurrently.

3. Current level: The rated current should be greater than or equal to the rated current of the controlled circuit. The starting current of the load should be less than the on-current of the contactor; hence, the breaking current should be more than the current needed for breaking while the load is operating. The rated current should likewise be suitably raised or lowered depending on the operating mode for motor loads. One can choose conventional calculations depending on the load rated current × 1.4-7 times;

4. Coil voltage and frequency: The rated voltage and frequency of the attraction coil should be consistent with the selected voltage and frequency of the control circuit. Furthermore taken into account are the line length and voltage loss to guarantee the contactor can run within the range of 85% to 110% of the rated voltage value.

5. Auxiliary contacts: The number and current capacity of the auxiliary contacts of the contactor should meet the control circuit wiring requirements.

6. Operating frequency: If the operating frequency of the contactor exceeds the specified value, the rated current should be appropriately increased.

7. Working environment: Consider the working environment of the equipment, such as temperature, humidity, dust, vibration and other parameters to select a suitable contactor model.

8. Installation and size: Consider the installation method and size of the contactor to ensure that it can adapt to the space inside the electrical product.

Which contactor types exist?

1. Classification by control coil voltage: DC contactor: Both contacts and electromagnetic relays are designed for DC circuits. AC circuits make especially use of electromagnetic relays and contacts.

2. Classification by operating structure: Electromagnetic contactor: Use electromagnetic suction to close or disconnect the main contacts of the motor circuit or other load circuit. hydraulic or pneumatic contactor

3.Direct-acting contactor, rotary contactor: classification by action mode

4.For some contactors that regulate the AC circuit in the contact system and the coil is connected to the DC circuit, classification by the type of the main contact on-off current: AC contactor, DC contactor, AC/DC contactor

5. Manual, electric, electromagnetic force attraction; operation mode classification

6. Classification: fixed, moveable depending on installation technique.

7. Classification by main contact form: normally open, normally closed.

8. Structural classification of electromagnetic contactor and permanent magnet contactor

9. Classification according to the surroundings of the primary contact point: air contactor, vacuum contactor

10. Classification according to main contact count: single-pole, multi-pole contactor

11.Small, medium power, large contactors and low power, medium power, high power contactors, chosen depending on the current and power necessary to be carried.

Modular Contactor UEC1 series

As an indispensable component of the electrical system, the correct selection and use of contactors is crucial to ensuring the safety of equipment and the stable operation of the system. Deep awareness of the main technical elements of contactors allows electricians to choose and implement them more precisely, therefore reducing possible electrical risks. As technology develops constantly and the demand for electrical systems rises, contactor research and development will keep on to give electricians more options and opportunities. Let’s keep learning and adjusting to keep ahead in this demanding electrical profession always.

Post time: 7 月-12-2024