Electrical systems are absolutely important in daily living and modern industries. As a key component in the electrical system, the correct use and maintenance of the contactor is essential to ensure the stable operation of the entire system. For electricians and electrical engineers, a fundamental ability is knowing the fundamental knowledge of contactors, their functioning concepts, and how to execute fault diagnosis. The five technical points of contactors will be thoroughly introduced in this article to enable readers to have a strong grasp of this vital tool.

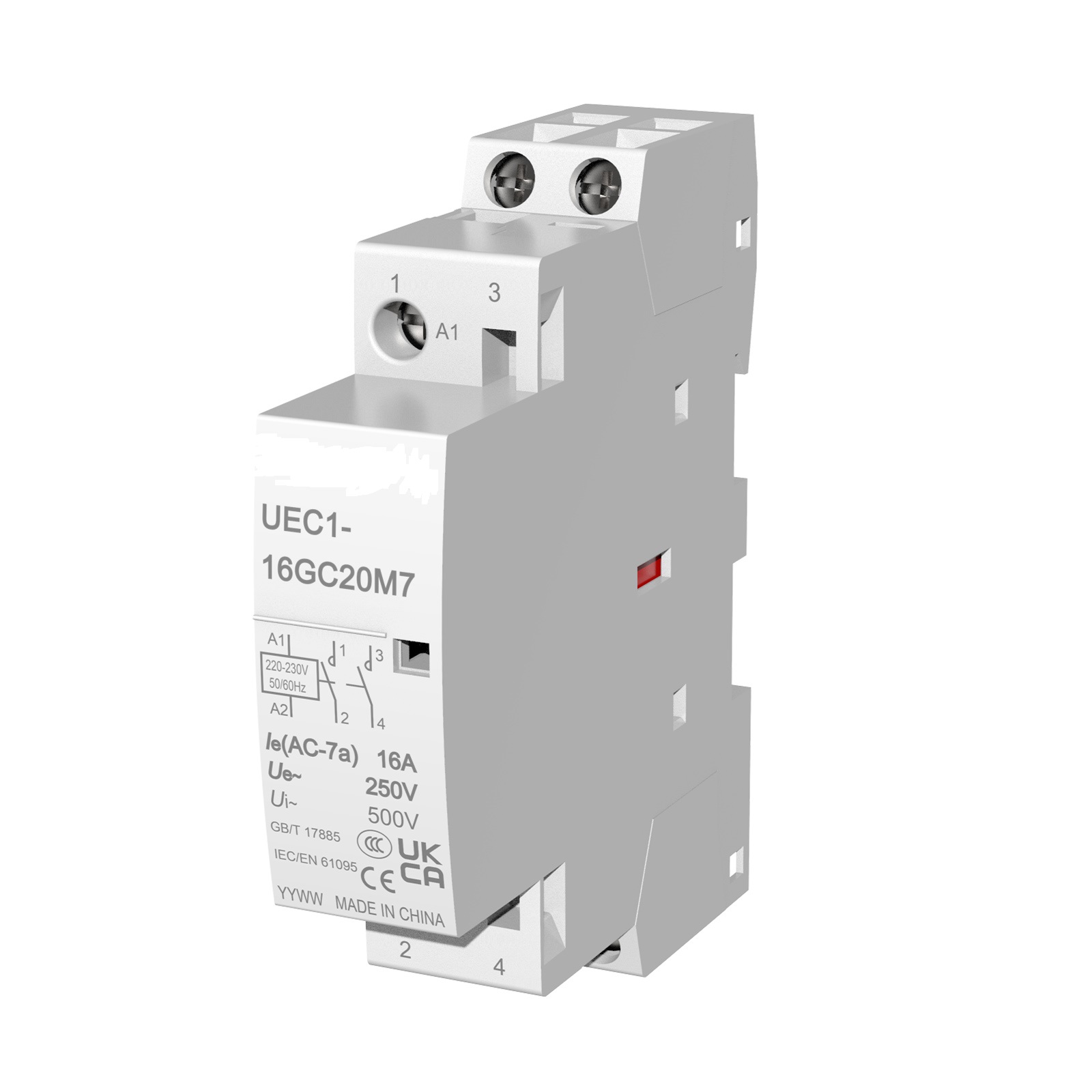

Modular Contactor UEC1 series

1. What are the main use occasions of contactors?

Among the most often used parts in industrial control systems are contactors. It is widely used in the control systems of large machines and equipment to control the operation of motors, lighting and other equipment through switching circuits. Additionally employed for control of pneumatic and hydraulic systems as well as automation control systems for different manufacturing tools are contactors. Additionally quite useful in transportation systems are contactors. For instance, contactor control opens and closes automatically doors and barrier doors on walkways in locations including trams, metro stations and train stations. Furthermore utilised in regular vehicles are contactors to regulate lights, electric windows and air conditioning systems. Moreover, contactors find use in systems of building automation. By means of switching circuits, contactors can regulate the switching, adjustment, and coordination of lighting and air-conditioning systems, so attaining energy saving and intelligent control especially in large commercial and residential buildings.

2. How should the working principle of the contactor be expressed?

The electromagnetic principle forms the foundation of the contactor’s functioning concept most of all. The coil current generated by an energised contactor coil will create a magnetic field that will attract the stationary iron core inside the contactor, therefore drawing the moving iron core. The two are related; the movement of the moving iron core will push the contact system of the contactor to move, therefore disconnecting the normally closed contact and closing the normally open contact.

Specifically, the contact system of the contactor includes main contacts and auxiliary contacts. Usually, the main contacts are used to link or disconnect the main circuit; the auxiliary contacts are used to regulate other elements of the circuit, such the conction control loop. Usually formed of silver-tungsten alloy, these connections have strong temperature ablation resistance and good conductivity. The electromagnetic attraction vanishes and the moving iron core is released under the action of the release spring when the coil is de-powered, so enabling the contact system to revert to its normal state—that is, the normally closed contact is closed and the normally open contact is disconnected. The contactor therefore finishes the control role of the circuit.

3. What is the relationship between the contactor and the Internet of Things?

The Internet of Things can be utilised in the electrical system to realise intelligent control and administration of electrical equipment by means of the contactor. The contactor can be utilised, for instance, with the sensor to identify the status or environmental characteristics of the electrical equipment, then subsequently to control the on and off of the equipment. Thus, the Internet of Things system may realise the purposes of remote monitoring, problem diagnostics and intelligent control of electrical equipment, and enhance the running efficiency and safety of the electrical system.

4. What do the interlocking, interlocking and self-locking of the contactor mean?

Though they have diverse purposes in the electrical control system, interlocking, interlocking, and self-locking are all meant to guarantee the steady and safe running of the system. One-on-one thorough study: Interlocking is the mutual constraint of two or more contactors in the same circuit to prevent simultaneous attraction and a short circuit. In particular, the typically closed contact of a contactor attracted will be detached, which will cause the coil of the second contactor to de-energize and therefore prevent the two contactors from being attracted concurrently. Mostly utilised in motor forward and reverse circuits, interlocking guarantees the safe running of the circuit. Interlocking, commonly known as interlocking, is the use of the auxiliary contacts of a given circuit to regulate the coil circuit of the other party so preserving the state or restricting the function. Usually employed to guarantee the safe and steady running of the system, this control mechanism helps to stop two or more actions from happening concurrently. For a mechanical manual gearbox, for instance, the interlocking mechanism serves to prevent two gears from being engaged concurrently. Self-locking is the phenomena whereby, by its own generally open auxiliary connections, the AC contactor always maintains the coil in an energised condition. Usually open auxiliary connections of the contactor coil will close to create a self-locking circuit when it is energised. In this sense, the contactor can remain in the energised condition to accomplish continued operation of the equipment even if the start button is disengaged. Usually used for continuous operation control of the motor, self-locking helps to increase the dependability and stability of the equipment.

5. How to use a multimeter to check the quality of the contactor?

Prepare instruments: You first require a multimeter and make sure its battery is enough to operate as intended. Choose a range of resistance. Change the multimeter range to the resistance range; usually, a lower resistance range will help you to more precisely estimate the contactor’s resistance value. Cut the contactor power supply. Make that the contactor has been unplugged from the power source before inspecting it to prevent electric shock.

Calculate the coil resistance by: Touch the two multimeter test pens to the two ends of the contactor coil, then note the multimeter’s reported resistance value. The contactor coil’s resistance value should be generally tens to hundreds of ohm. Should the resistance value be either too great or too small, contactor damage could be indicated. After that, find the contact resistance of the contactor. Close the contact of the contactor; then, touch the two test multimeter pens to the two ends of the contact. Should the contact be normal, the multimeter should show a tiny resistance value near zero. Should the resistance number be either huge or infinite, it could indicate poor contact or damage to the contact. Watch the exam procedure: Watch whether the multimeter’s display is steady during the measuring operation. Should the display be unstable, it could be that the contactor’s interaction suffers with stuck or jitter during the action. Decide the outcome: Judge whether the contactor is good or terrible depending on the aforementioned measurement findings. Should the test process be stable and the coil resistance and contact resistance fall within the normal range, the contactor should be normal. On the other hand, should the resistance value be aberrant or the test method be unstable, the contactor can suffer damage or other issues.

AC Contactor UEC1 series

Through the above discussion of the five technical points of the contactor, we can see the wide application and importance of contactors in electrical systems. From its use in several industrial and civil events, to its working principle based on electromagnetic principles, to its combination with the Internet of Things, the technical characteristics and application scenarios of the contactor show its indispensible position in modern electrical systems. Key abilities to guarantee the safe and stable running of the electrical system are also knowledge of interlocking, interlocking and self-locking as well as learning to use a multimeter to inspect the contactor. Although the design and operation of the contactor are also continuously improving with technological progress, for electricians, mastery of these fundamental knowledge points is still the foundation for delivering excellent electrical services.

Post time: 7 月-12-2024